Engineering Applications

AME-5001

Group - II

The work for Manufacturing the punch started when the Assignment was announced by our Tutor. So our work was divided in to approximately 9 weeks. So we can define our progress in weeks. Here is all the progress we made in those 9 weeks which was weekly maintained on our blog.

Week 1

This week was mainly the routine work in which the tutor gave us all the information and description regarding the module 'Engineering Applications - AME5001' and also the assignment from this module 'Manufacturing of Punches' . This module mainly deals with practical group works. The groups were chosen by tutor.

Week 2

In this week, we were more introduced about our assignment and taking a step ahead wwere asked to select a punch to design and manufacture. We were informed about the Aims & Objectives of the punch. We selected 'Centre Punch' because it was commonly used worldwide and lots of data was present on Websites and internet which will help in this assignment.

Week 3

This time the tutor took us to the Group meeting room or the Disscussion room to do the following things:

(i) Select a type of punch you want to Design & Manufacture.

(ii) Try to draw and produce a Rough Design

(iii) Explain the reason behind choosing this type of punch ?

(iv) Produce a Blog which will contain all the information about your Progress which should be maintained regularly.

(v) Get it attested from the tutor.

Week 4

With the passed design every member of the group was required to produce a detailed 2D Drawing. As we all agreed and gave ideas and our design was already attested from the tutor in the last week, we all submited the 2D Drawings (by each member) to the tutor and she completed the formality.

SOLIDWORKS was also recommended for designing the 2D and 3D drawings.

Week 5

This week we Gathered information from different sources to understand how the Lathe works and the Process the Lathe Machine can undergo to produce a product. We came up with 4 Lathe process which we will be using to produce our Punch. The 4 Lathe Processess is:

-

Turning

-

Chucking

-

Taper turning

-

Facing

-

Knurling

The tutor then told us to research on further information on how the Normal Lathe machine is setup and the different types of tool tips and how they are setup and update this information on the Blog.

Week 6

We researched about the Centre punch referred to some books and updated our blog.

Week 7

This week was the most important and most practical week. This week we were taken to mechanical workshop which consists of CNC and Normal lathe machines which were used to manufacture Punches. Our 2D design was already sent to them and they had examined it properly. We were the second group and we went for Normal Lathe machine which was available at that time.

Week 8

This week we were made to update the blog on the Punch. We also need to choose a type of heat treatment for our punch, why it is required? and other types of heat treatment. We will need to update the blog on these terms as well

Week 9

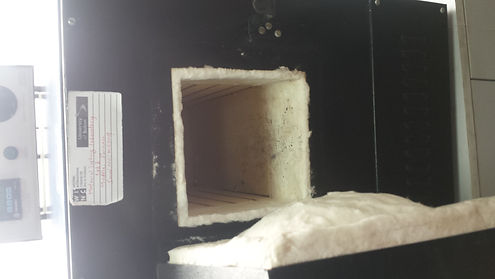

This week was Heat Treatment. As Groups we all Heated our Punch in the Muffle Furnace to around 890-900 Degree Celcius, after which we rapidly cooled the Workpiece in Water. We then went to the tampering process to bring back the workpiece's hardness. This process involves heating the workpiece to 300-400 Degree Celcius with a blow tourch and then allowing it to slowly cool with the surrounding temperature.

Testing

In the same week, a day after the heat treatment we tested the strength of our punch by putting the punch on a surface and hitting it with a Hammer.